Every restaurant owner knows that food costs are a major factor in profitability. But there’s a hidden cost lurking in every dish that many operators underestimate: labor. Specifically, the time it takes to prep ingredients before service.

That house-made aioli? It’s not just eggs and oil—it’s five minutes of a line cook’s time. That beautifully diced mise en place? It’s hours of labor before a single ticket prints. And in an industry where labor costs can eat up 30-40% of revenue, inefficiencies in prep work can silently drain your profits.

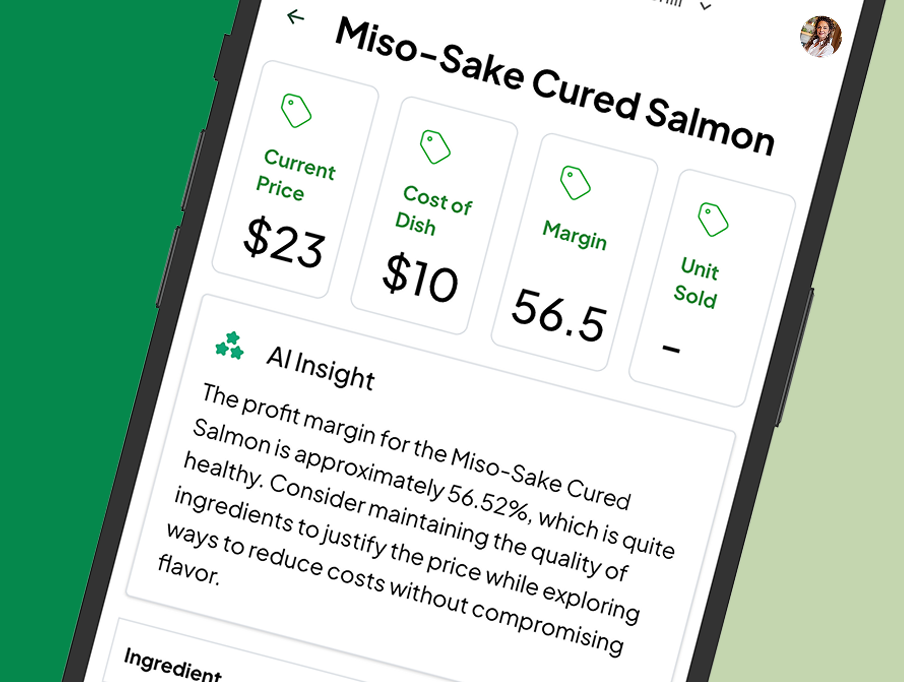

For small and medium-sized restaurants, understanding and optimizing prep time is essential. MRGN, a financial intelligence platform designed for restaurants, helps owners and operators gain visibility into these hidden costs—so they can make informed decisions about staffing, pricing, and efficiency.

In this article, we’ll break down the labor costs behind every dish, explore the impact on profitability, and offer actionable strategies to streamline prep without sacrificing quality.

The True Cost of Prep Work

The Clock Is Always Running

When calculating food costs, most restaurants focus on ingredients. But every slice, chop, and stir costs money in wages.

Consider this:

- If a restaurant employs a prep cook at $18 per hour, and that cook spends four hours each day chopping vegetables, making sauces, and portioning proteins, that’s $72 per day just on prep labor.

- Over a 30-day month, that adds up to $2,160 in prep labor costs—before factoring in payroll taxes, benefits, or overtime.

- If a restaurant operates on a 5% profit margin, it would need $43,200 in additional revenue just to cover that one cook’s monthly wages.

Now multiply that by multiple employees, multiple shifts, and the reality of kitchen inefficiencies, and it’s clear why unoptimized prep work can be a silent killer of profits.

Labor Costs vs. Menu Prices

Most restaurants price their menu items based on food costs, aiming for a 30-35% food cost percentage. But without factoring in prep labor, they may be underpricing their dishes.

For example:

- A restaurant serves a $15 pasta dish with a food cost of $4.50 (30%).

- But if the dish requires 20 minutes of prep per batch, and a line cook earning $20/hour handles the prep, that’s an additional $6.67 in labor per batch (before service labor).

- If that batch yields 10 servings, the true cost per dish jumps to $5.16.

- At a 30% target cost, the dish should be priced at $17.20—not $15—to account for labor.

Without recognizing these hidden costs, restaurants may be unknowingly undercutting their margins on popular dishes.

The Impact of Inefficient Prep

Overstaffing and Underutilization

Without clear visibility into prep labor, many restaurants overstaff shifts, paying employees to do work that could be streamlined or eliminated.

- A restaurant might schedule two prep cooks when one well-trained cook could handle the workload with the right efficiencies.

- Cooks might be spending time on low-value tasks (like peeling potatoes by hand instead of using a peeler attachment).

- Too much prepped inventory can lead to waste, while too little can slow down service.

Increased Payroll Costs and Burnout

Labor inefficiencies don’t just cost money—they contribute to kitchen burnout.

- If prep work takes longer than expected, cooks stay late—leading to overtime costs or overworked employees.

- Last-minute prep during service slows down the kitchen and frustrates the team.

- Poor scheduling leads to higher turnover, increasing training costs and disrupting operations.

By analyzing how much time is actually required for prep, restaurants can schedule smarter, reduce waste, and protect their bottom line.

Optimizing Prep Time for Profitability

Measure and Track Prep Time

Just as restaurants track inventory and sales, they should be tracking prep time per dish.

How MRGN Helps:

- MRGN allows operators to see the full picture of their labor costs, helping them pinpoint where prep inefficiencies are cutting into profits.

- By integrating with scheduling tools, restaurants can match labor needs to actual demand—preventing overstaffing and overtime.

- Owners can compare actual vs. estimated prep times to make data-driven decisions.

Reduce Labor-Intensive Dishes

Not every ingredient needs to be prepped in-house. Restaurants should evaluate:

- High-labor items: Is house-made pasta truly necessary, or would a high-quality pre-made version suffice?

- Batch efficiency: Can sauces and stocks be made in larger quantities to reduce daily labor?

- Pre-portioned ingredients: Would pre-cut vegetables or pre-trimmed meats save enough labor to justify the cost?

Invest in Equipment That Cuts Prep Time

Time-saving equipment isn’t just for large chains—it’s an investment that pays for itself.

Consider:

- Food processors for slicing, dicing, and shredding.

- Vacuum sealers to extend the life of prepped ingredients.

- Automated portioning tools to speed up consistency and reduce waste.

If a $2,000 piece of equipment eliminates 10 hours of weekly labor, it could pay for itself in a few months.

Optimize Scheduling Based on Data

Rather than relying on gut instinct, use data to optimize staffing.

- Schedule prep shifts during off-peak hours to maximize labor efficiency.

- Adjust prep workload based on historical sales data—not just assumptions.

- Use MRGN’s forecasting tools to anticipate demand and avoid wasted labor.

The Bottom Line: Every Second Counts

In the restaurant industry, every minute of labor is a cost. And while chefs are passionate about scratch-made food, passion doesn’t pay the bills.

By tracking prep time, evaluating labor-heavy tasks, and leveraging data-driven decisions, restaurants can reduce labor costs without sacrificing quality.

With MRGN, restaurant owners don’t have to guess whether they should add staff, cut hours, or adjust menu pricing. They can see exactly where their labor dollars are going—and make smarter, more profitable choices.

Because in the restaurant world, success isn’t just about what’s on the plate—it’s about what happens before service even begins.

Ready to Take Control of Your Restaurant’s Labor Costs?

MRGN helps restaurants optimize costs, track profitability, and make informed financial decisions—without the need for a CFO.

Start your MRGN Free 2-Week trial today and see how smarter labor management can save your restaurant thousands.